Xinghua Dongchang Alloy Steel Co., Ltd (olim Xinghua Dongchang Alloy Ferro Factory) est fabrica ferri et offensionis utilitas mittentes producta in Sinis. Constituti sumus mense Augusto MMVI apud Facem National Plan Sinis Alloy Ferro emittentes Base.

V summus perficientur applications de Calor repugnant ferro materia artus castings

Ut industries dis operational limites: calor repugnant ferro materia artus castings sunt becoming discrimine components. Haec specialioribus castings ponere sistens integritas in extrema environments, offering superior perficientur comparari conventional alloys. Infra sunt quinque clavem longa-cauda Phrases cum low competition sed princeps relevance:

- Altum Temperature Steel mittentes fornacem partibus

- Calor repugnant frame castings pro Industrial in Carl

- Custom calor repugnans ferro components ad aerospace

- Dura Steel castings ad exhauriunt systems

- ROSIO resistant ferro tabulas pro chemical processus

Quare Calor repugnant ferro artus castings Sunt revolutionizing industries

In demanda ad materias, quae resistere extrema condiciones quae nunquam fuisse altius. Ex industria plantis ad aerospace, calor repugnant ferro materia artus castings Provide solutions ubi traditional metalla deficient.

I. Material proprietatibus et perficientur commoda

Haec specialioribus castings miscere Chromium, Nickel, et Molybdenum ad partum eximia scelerisque stabilitatem. Dissimilis Latin Carbon Steel quod incipit infirmata ad CD ° C, calor resistit grades ponere:

- XC% of tensile vires ad DCL ° C

- Oxidatio resistentia ad MCL ° C

- Repente resistentia sub continua onere

Comparative perficientur data:

| Res | Vexillum ferro | Calor repugnant gradu |

|---|---|---|

| Max Service Tempus | CDL ° C | MC ° C |

| Rate oxidatio | High | 0.5mm / 1000hr |

| Scelerisque expansion | 13.5 μm / m ° C | 16.2 μm / m ° C |

II. Key vestibulum processus pro High Temperature Steel mittentes fornacem partibus

Productio ex his components requirit specialized artes ut qualitas:

2.1 investment casting modum

Delivers superior superficies metam et dimensional accurate ad universa geometries. Processus involves creando tellus fingit quod resistere extrema effundens temperaturis 1600-1700 ° C requiritur ad haec alloys.

2.2 Post-casting calor curatio

Critica ad consequi bene microstructure. SOLUTIO annealing ad ML ° C secutus per celeri extinguitur evolvit desideravit Austenitic structuram quod providet scelerisque stabilitatem.

Industry-specifica solutions usura æstus repugnant frame castings

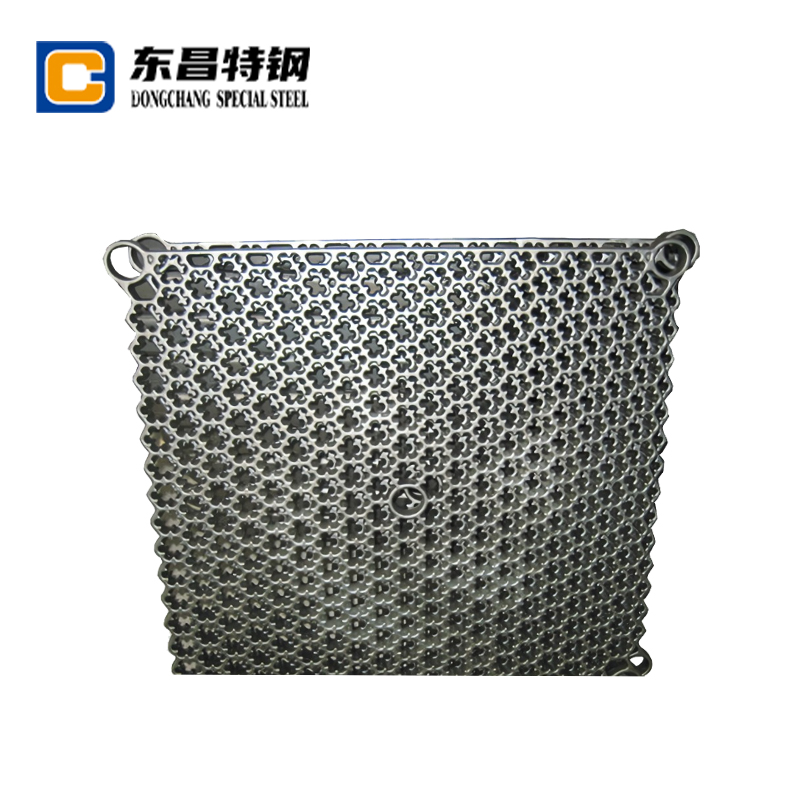

3. Calor repugnant frame castings pro Industrial in Carl in cibum processus

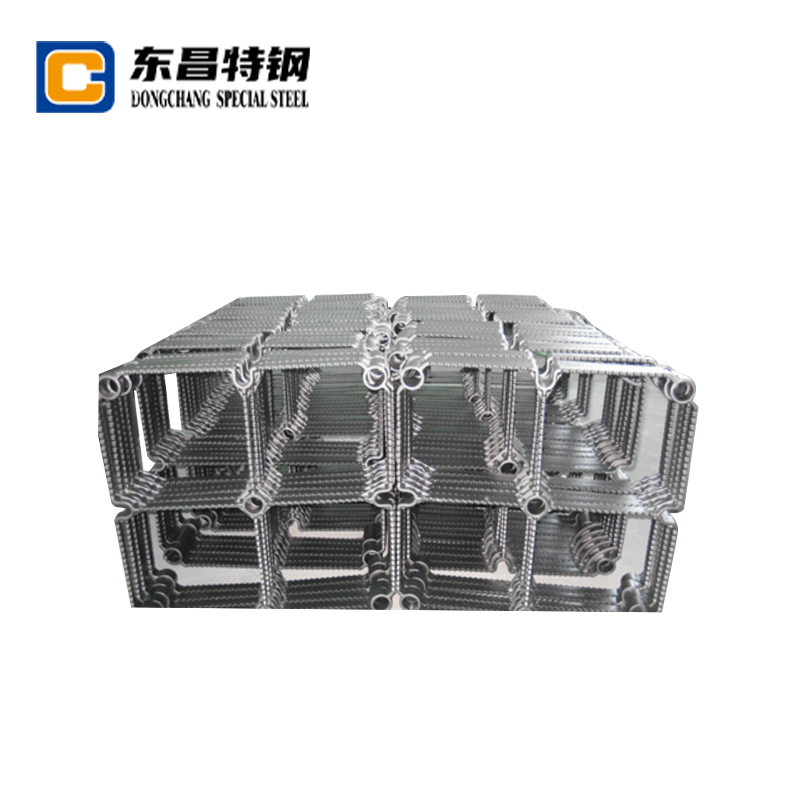

Moderni cibum productio requirit in furnos esse ponere precise temperaturis dum resistente corrosio a elit eget. Calor repugnant projiciam tabulae offer:

- L% diutius servitium vitae quam welded tabulas

- Eliminanda scelerisque distortione ad 300-600 ° C Operating Ranges

- Hygienic Designs cum minimam articulis

4. Custom calor repugnans ferro components ad aerospace Applications

Jet engines et afterburner components demanda materiae, quae praestare sub extremam scelerisque cycling. Aerospace-gradus castings providere:

| Postulationem | Solution |

|---|---|

| PRAETENDO | Nickel-fundatur superalloy Castings |

| Exhaurit frame rigiditate | Praecisione Castensitic ferro |

| Thermal lassitudine resistentia | Special Frumentum structura Imperium |

V. progressiones in Dura Steel castings ad exhauriunt systems

Modern emissionem systems eget materiae, quae resistere tam altum temperaturis et mordax exhauriunt vapores. Recent includit developments:

5,1 melius Alloy Compositionibus

Insuper de rara terra elementa enhances oxidatio resistentia dum maintaining ductilis. Novum grades ostende XXX% magis scelerisque cycling euismod.

5,2 innovative refrigerationem channel consilia

Mittentes technology nunc concedit universa internum refrigerationem locis, quae sunt ante impossibile cum fabricatione modos.

Emergentes applications in eget processus

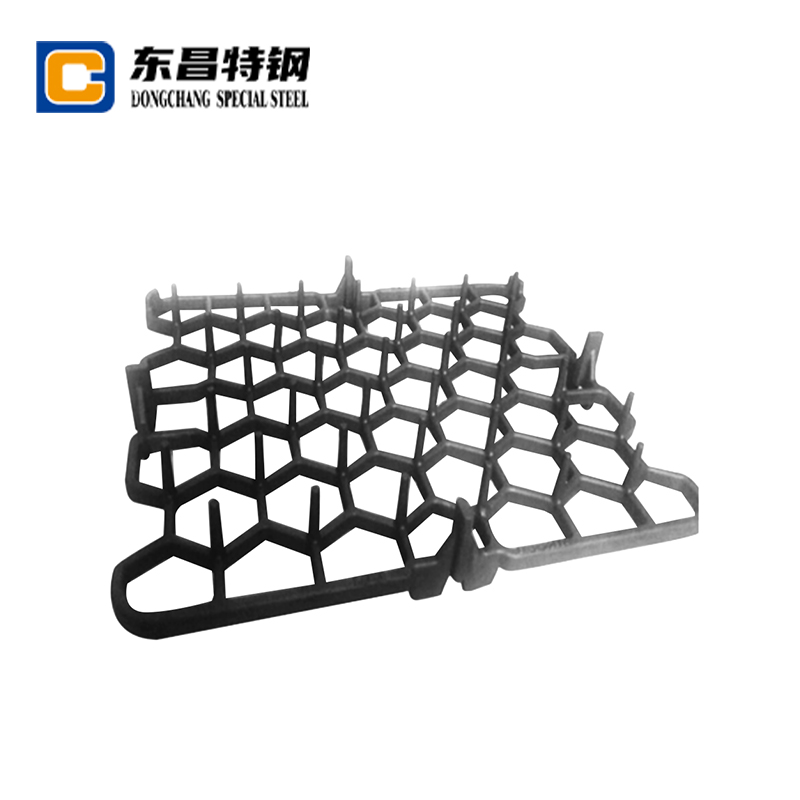

Opus est ROSIO resistant ferro tabulas pro chemical processus Pellentesque materiam innovations:

- Chloride-repugnant grades ad acidum environments

- Summus puritas castings ne contamination

- Thermal concursu repugnant consilia

Hae Applications demonstrare quomodo calor resistit ferro castings solve multiple engineering challenges eodem tempore.

Future trends in summus temperatus materia technology

Research focuses in developing castings ut dis temperatus fines dum reducendo pondus et sumptus. Nanostraurtructured Alloys et 3D-typis formae repraesentant proximo finitum pro his discrimine components.

+86-15861061878

+86-15861061878