Xinghua Dongchang Alloy Steel Co., Ltd (olim Xinghua Dongchang Alloy Ferro Factory) est fabrica ferri et offensionis utilitas mittentes producta in Sinis. Constituti sumus mense Augusto MMVI apud Facem National Plan Sinis Alloy Ferro emittentes Base.

Calor curatio fornacem partes ludere a discrimine partes in industriae processus, ensuring optimal scelerisque perficientur et diuturnitatem. Hi components, una cum Alloy Steel impuller castings et fornacem parce partes castings, sunt vitalis est industries ut metallurgy, aerospace, et potentia generationem.

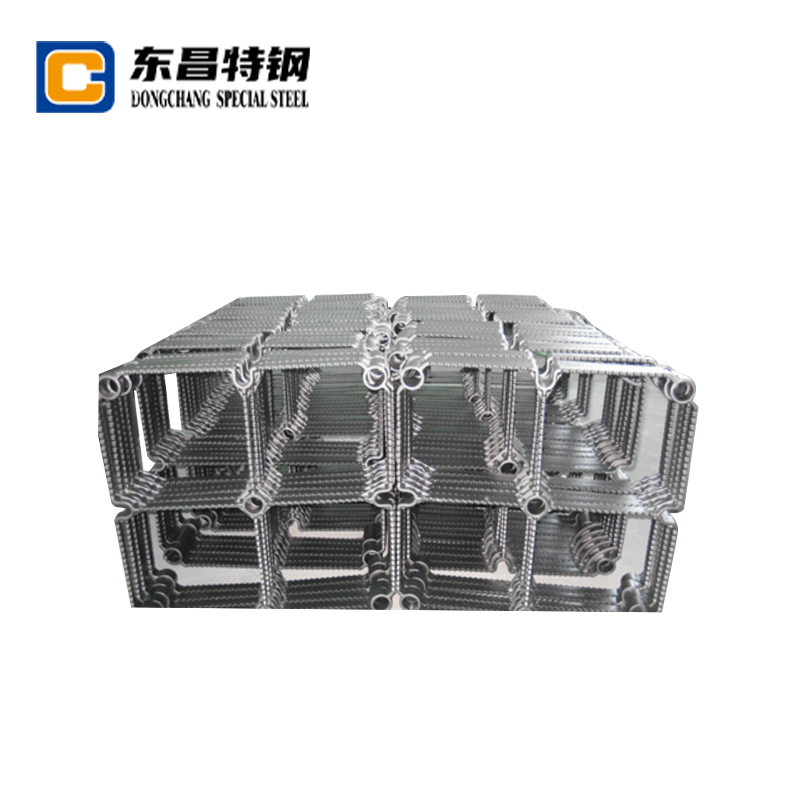

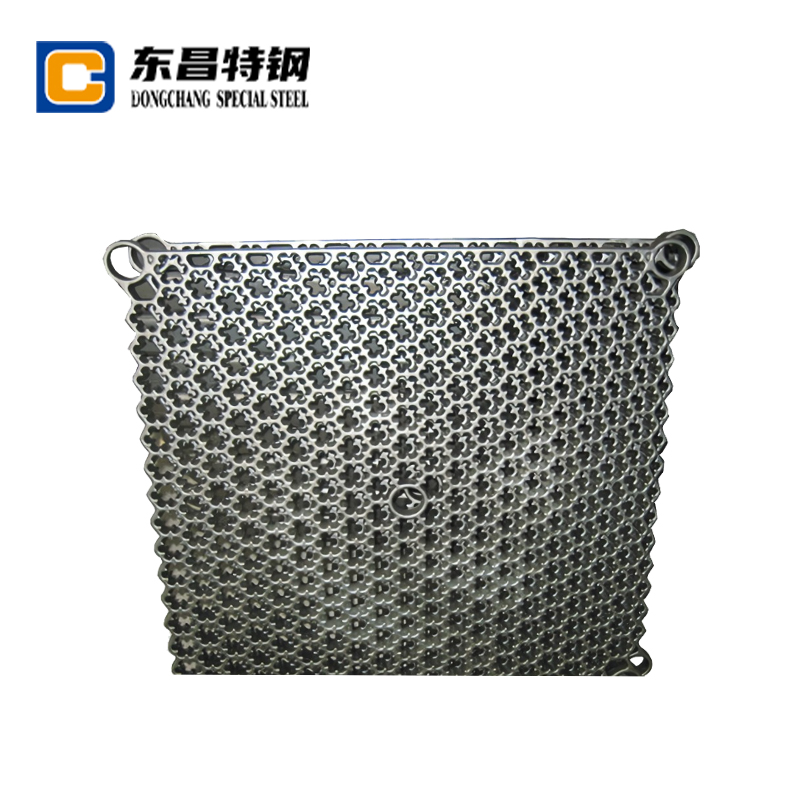

Calor repugnans ferro fornacem scutulis castings

Key components in Calor curatio furnas

Calor curatio furnas confidunt in altus-perficientur partes ponere precise temperatus imperium et Vivacitas. Quidam essential components includit:

Calefacere elementa - resistentia vel Silicon carbide virgas ad uniformem calor distribution.

Quenching systems - nam celeri frigefaciendo tractata metalla.

Nulla Materias - Ceramic fibra et Refractius lateres ad minimize calor damnum.

Fornacem Fixtures & - summus temperatus-resistant alloy subsidiis in workpieces.

Alloy Steel impuller castings : Fortitudo & diuturnitatem

Alloy Steel impulsor Castings late usus est in pumps, turbines et compressors propter eorum superior mechanica proprietatibus. Key advantages includit:

Altum Tensile - Resistit deformatio sub accentus.

ROSIO resistentia - idealis pro dura ambitus.

Gerunt resistentia - Prostringit vitae operational in abrasive conditionibus.

Material Comparison: Alloy Steel vs Steel Impellers

| Res | Alloy Steel impellers | Immaculatam ferro impellers |

|---|---|---|

| Tensile vires | 850-1000 MPA | 500-700 MPA |

| Corrosio resistentia | Moderor | Altum |

| Efficientiam sumptus | Altum | Ad altum moderari |

| Typical applications | Altus-pressura pumps, turbines | Chemical Processing, Marine Applications |

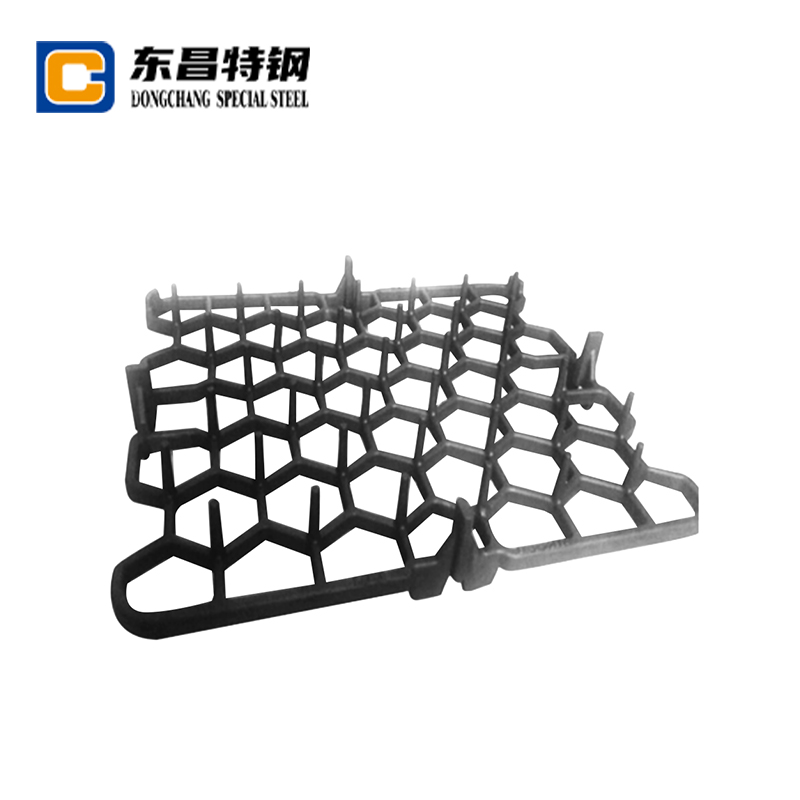

Fornacem parce partes castings : Continuatur ensuring operationes

Fornace parce partes castings, ut exuro nozzles, rationes, et calor, oportet resistere extremam scelerisque cycling. Communis materiae includit:

Altum, Chromium cast ferrum - optimum æstus resistentia.

Nickel, secundum Alloys - superior oxidatio resistentia.

Ceramic, adiutriced compositor - amplificata scelerisque inpulsa resistentia.

Perficientur collatio communi fornacis casting materiae

| Material | Max Operating Temp. | Scelerisque inpulsa resistentia | Cost |

|---|---|---|---|

| High-C Mittite ferrum | M ° C | Moderor | Humilis-medium |

| Ni-secundum Alloneys | MCC ° C | High | High |

| Ceramic Composites | MCD ° C | PERPREPIDUS | PERPREPIDUS |

Calefacere curatio fornacem partibus, ally ferro impuller castings, et fornacem parce partes castings sunt necessaria in industriae applications. Discriptis ius materiae ensures efficientiam, diuturnitatem, et sumptus-efficaciam. Per comparet clavis parametri, industries potest facere certiorem decisiones ad optimize perficientur et redigendum downtime.

+86-15861061878

+86-15861061878