Xinghua Dongchang Alloy Steel Co., Ltd (olim Xinghua Dongchang Alloy Ferro Factory) est fabrica ferri et offensionis utilitas mittentes producta in Sinis. Constituti sumus mense Augusto MMVI apud Facem National Plan Sinis Alloy Ferro emittentes Base.

Intellegentia Alloy Steel Material Tray Castings et industrialis significationem

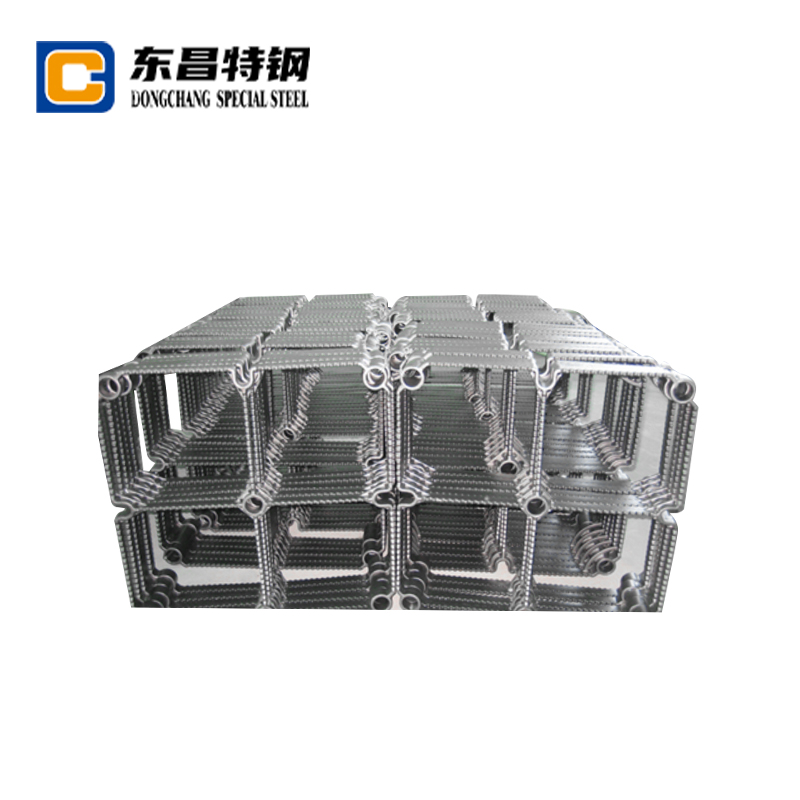

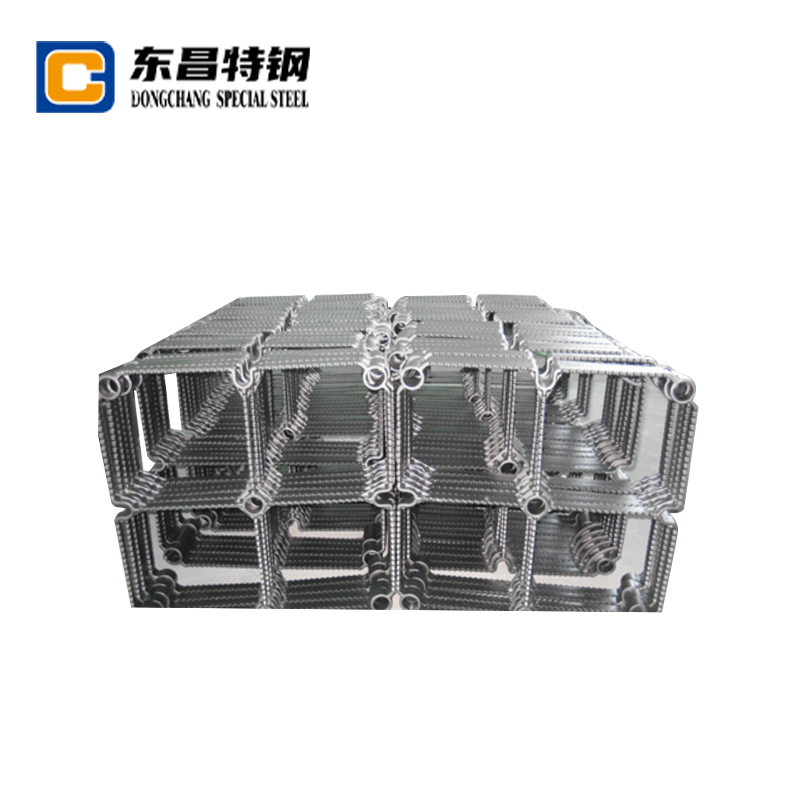

Alloy Steel Tray Castings sunt Critical Components in gravibus-Officium Industrial Applications, offering superior fortitudo, diuturnitatem et resistentia ad extremam conditionibus. Haec castings sunt machinatus ad sustinere altum accentus, corrosio, et gerunt, faciens eos necessarios in sectores ut metalla, constructione et vestibulum. De unique compositionem of allimis ferro, typically incorporandi elementa sicut Chromium, Nickel, et Molybdenum-Enhances suum mechanica proprietatibus extra Latin Carbon ferro.

Key characteres de Alloy Steel Tray Castings

Alloy Steel Tray Castings ex ex eximia proprietatibus:

- High Tentile fortitudinem: Capax ferre gravibus onerat sine deformatio.

- Gerunt resistentia: Specimen pro abrasive environments debitum ad obfirmat superficiei.

- ROSIO resistentia: Perficit bene in humidum vel chemica infestantibus occasus.

- Thermal Stabilitatem: Maintains structural integritas sub alte temperaturis.

Comparari ad vexillum ferro, Alloy Steel Tray Castings offer 20-30% maiorem lassitudinem vitae, ut demonstratum in industriae accentus probat. Infra est collatio key metrics:

| Res | Alloy Steel Tray Castings | Latin Carbon Steel |

|---|---|---|

| CEDITAS | 550-850 MPA | 250-400 MPA |

| Impact resistentia | Princeps (50-100 J ad -40 ° C) | Moderare (20-40 J at -40 ° C) |

Beneficia usura More Alloy Steel Trays in gravibus Machinery

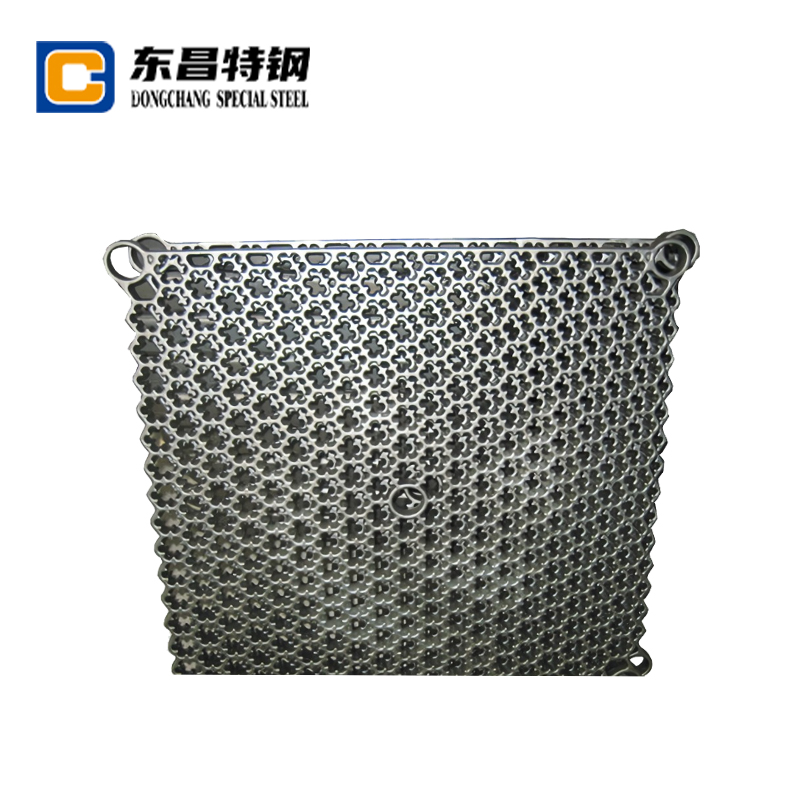

Custom Alloy Steel Wrays Providere Tailored Solutions ad specialioribus apparatu, ensuring optimal perficientur in exposcens operationes. Quorum accommodability concedit ad praecise dimensional figuras, pondus distribution, et onus-afferentem capacities.

Applications in discrimine Industries

Hi sunt late usus est in:

- Mining: TRADUCTOR Systems et Ore Processing Equipment.

- Energy: Turbine components et potestatem tradenda partes.

- Translationem: Gravis vehiculum undercarriages et cargo subsidiis.

A casu studium in metalla operationes ostendit quod More Alloy Steel Trays reducta sustentationem downtime per XLV% comparari generali alternatives.

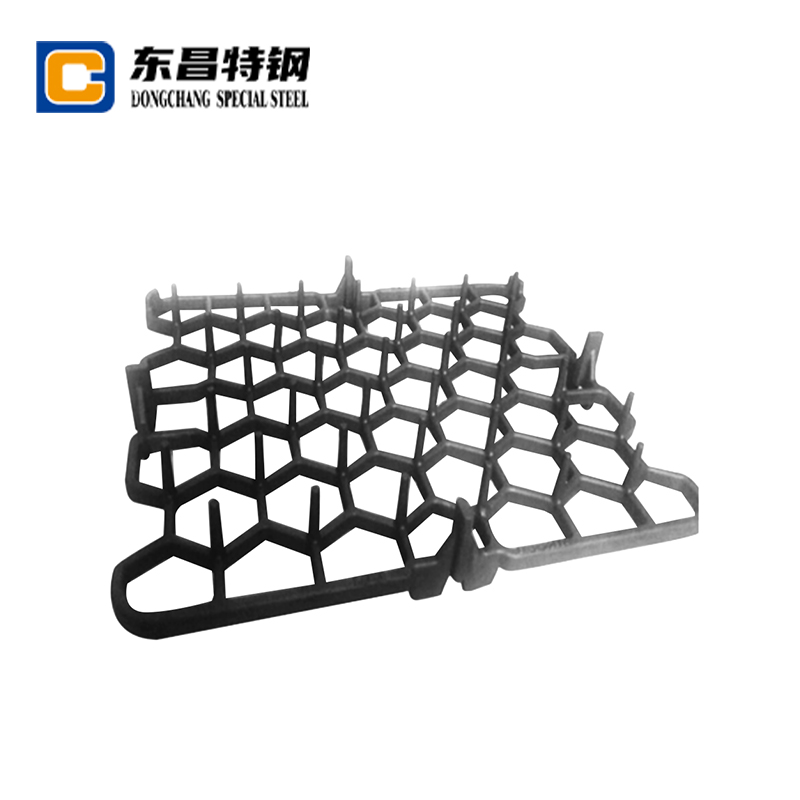

Calor Treatment processuum enim auctus Alloy Steel Tray Duerutility

Calor treatment est in maxima in perficientur de permaneo malleat. Processus sicut extinxit, temperatio et annealing mutare microstuctructure ad consequi desideravit duritia et lenta.

Communi calor curatio artes

Infra sunt maxime modos:

- Quenching: Celeri refrigerationem ad augendam duritia.

- Temperatio: Reheating ad redigendum fragtileness.

- Casus Hurdening: Superficies amplificationem ad induendum resistentia.

Data ostendit quod recte calor, tractata Alloy Steel Trays Exhibeant LX% iam servitium vitae in abrasive environments.

Comparet Alloy Steel vs Steel Tray Castings ad Industrial Use

Dum tam materiae robust, eorum idoneitate dependet in propria operational requisita. Alloy Steel excellit in summus accentus applications, cum immaculatam ferro offert superiori corrosio resistentia.

ERECTIO

| Criteria | Alloy Steel Tray Castings | Aliquam Steel Tray Castings |

|---|---|---|

| Efficientiam sumptus | Superiore (Ob specialized Alloys) | Inferius (ad Standard Grades) |

| Sustentationem frequency | Moderatus (requirit coatings) | Humilis (inerat, corrosio repugnans) |

Nam industries prioritizing onus capacity super corrosio resistentia, Alloy Steel Material Tray Castings sunt patet arbitrium.

Quam eligere ius Alloy Steel gradu pro Tray casting Applications

Eligendo oportet quodammodo steel gradu involves aestimandis operational stressors, environmental conditionibus et budget coactus.

Key lectio criteria

- Mechanica onerat: Superiore grades (E.G., (IV) CXL) ad dynamic passiones.

- Temperature extremorum: Chromium, Molybdenum Alloys ad scelerisque stabilitatem.

- Corrosio nuditate: Tempestas repugnans Steels ad velit usus.

Engineers commendare consulting ASTM vel ISO signa cum specificationem Alloy Steel Trays in High-Temperature environments ut obsequio.

+86-15861061878

+86-15861061878