Xinghua Dongchang Alloy Steel Co., Ltd (olim Xinghua Dongchang Alloy Ferro Factory) est fabrica ferri et offensionis utilitas mittentes producta in Sinis. Constituti sumus mense Augusto MMVI apud Facem National Plan Sinis Alloy Ferro emittentes Base.

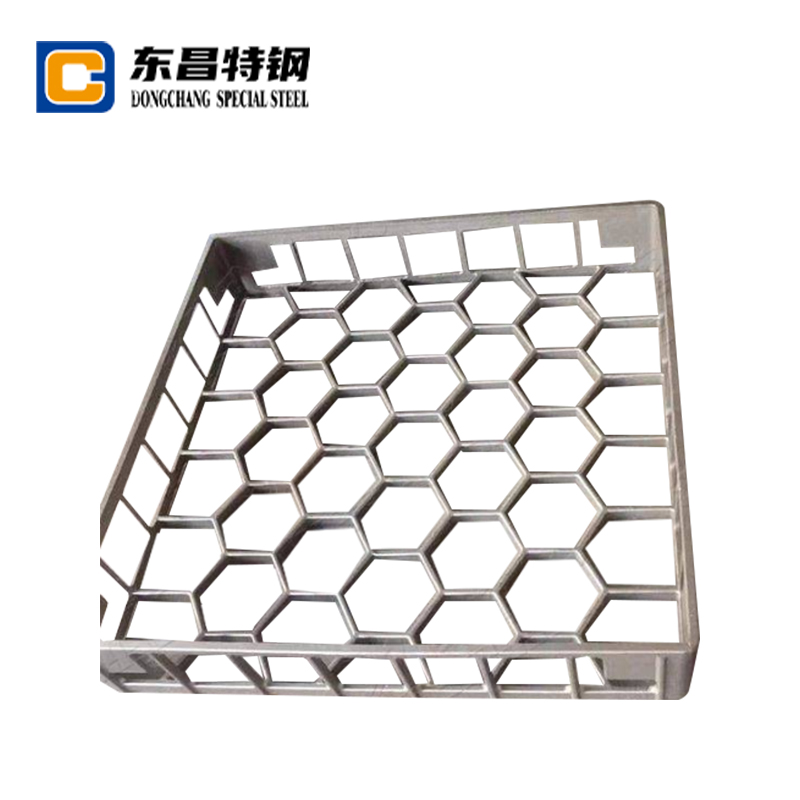

Intellegentia Calor repugnant ferro artus castings

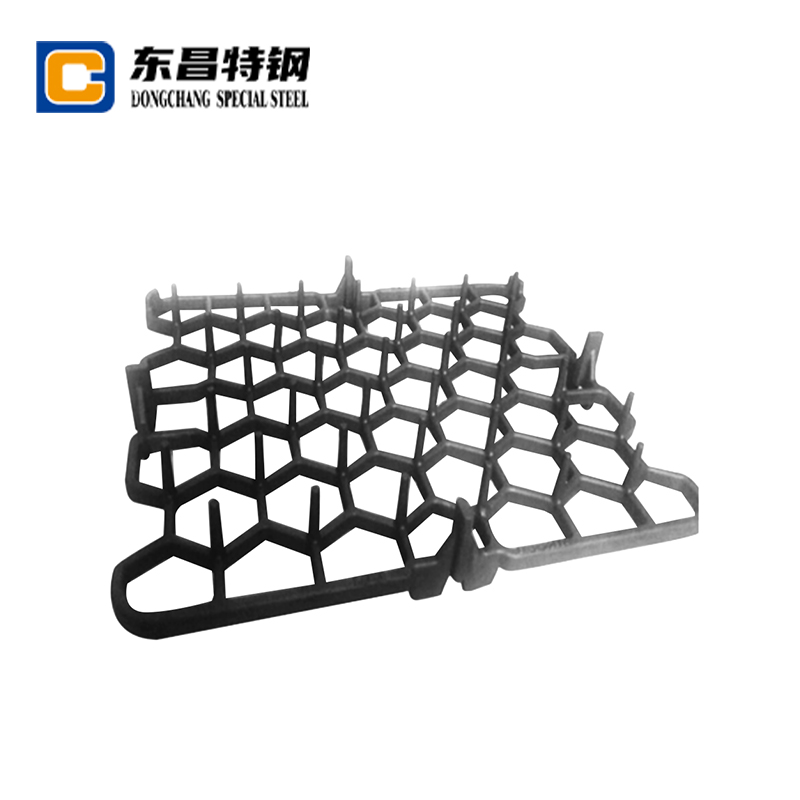

Calor repugnans ferro materia artus castings sunt specialioribus components disposito ad resistere extrema temperaturis dum attendendo structural integritas. Hae castings ludere a crucial partes in industries ubi summus temperatus operationes sunt exercitatione, offering superior perficientur comparari ad vexillum ferro alloys. In Optimus calor resistant ferro Alloys ad Industrial Castings Miscere eximia scelerisque stabilitatem cum mechanica vires, faciens ea necessaria postulans applications.

Calor repugnant et summus temperatus repugnant materia frame castings

Key characteres calor repugnant ferro castings

Haec proprietatibus proprietatibus proprietatibus exhibent quae se extra conventional ferro

- Optimum oxidatio resistentia ad elevatum temperaturis

- Altus serpit resistentia sub sustineatur onera

- Bonum scelerisque lassitudine proprietatibus

- Retention of mechanica vires ad altum temperaturis

- Resistentia ad scalas et corrosio in calidum environments

Microstructural commoda

Superior perficientur calor repugnans ferro castings caulibus ex diligenter machinator microstructure. Alloying elementa sicut Chromium, Nickel, et Molybdenum forma stabilis carbides et intermetallic augmenta ut ne degradation ad altum temperaturis. Hoc microstructural stabilitas est quod facit eos Top choice in altum temperatus frame components In discrimine applications.

Applications de calor repugnant ferro artus castings

Unicum proprietates harum materiae faciunt idoneam numerosis industriae applications ubi temperatus extrema offendit. Quorum usum palmis trans plures sectores, ex industria productio ad vestibulum processus.

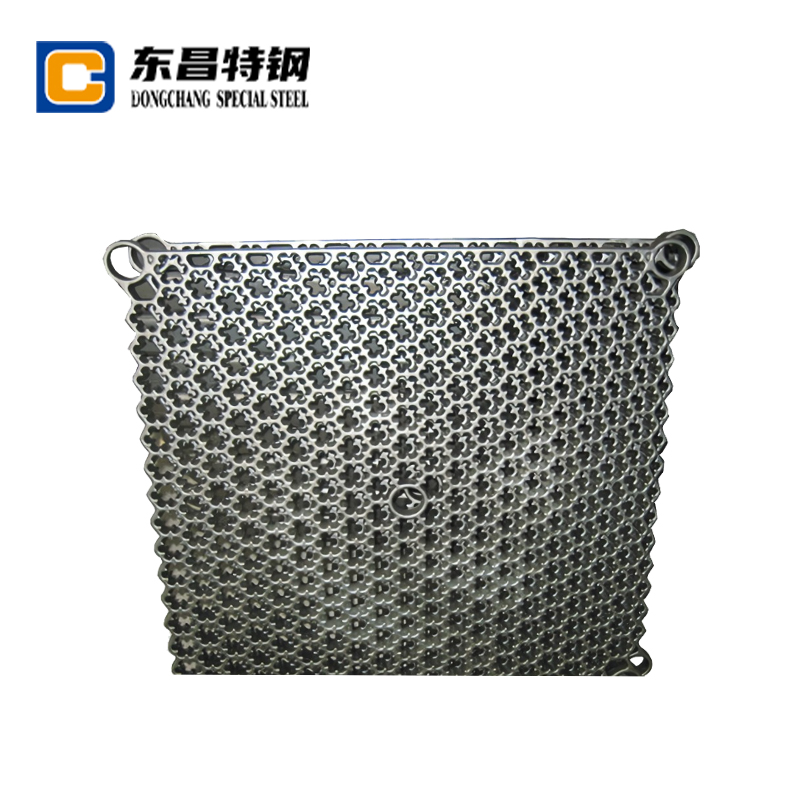

Industrial fornace components

Calor repugnant ferro castings formare structural compage of industriae furnorum, withststanding continua nuditate ad temperaturis nimis M ° c. Haec components includit:

- Fornacem fores et tabulata

- Calor curatio canulas

- Rollerus Hearth Systems

- Exuro nozzles et sustinet

Power Generation Equipment

In potentia plantis, Dura calor repugnant casting solutions Sunt essentialia pro components sicut Turbine Housings, boiler subsidiis et exhauriunt systems. Partes pati tam altum temperaturis mechanica passiones in ministerium vitae.

Comparet calor resistant ferro grades pro artus castings

Diversis gradibus calor resistant ferro offer vario perficientur characteres. Intelligentes haec differences est crucial cum eligens Sumptus-efficens calor repugnant frame materiae Nam propria applications.

Communis calor resistant ferro grades

| Gradus | Maximum Service Temperature | Key Offering elementa | Primaria applications |

|---|---|---|---|

| HK30 | MC ° C | 25cr-20NI | Fornacem partes, radiantur fistulae |

| HP40 | MCL ° C | 25Cr, 35NI-NB | Petrochemical fornace components |

| 310 | ML ° C | 25cr-20NI | Calor curatio apparatu |

Lectio criteria

Cum eligens inter diversas grades considerans haec factores:

- Operating temperatus rhoncus

- Cyclic vs. continua calefactio

- Mechanica onus requisitis

- Atmosphaera (oxidizing, reducendo, etc)

- Scelerisque inpulsa potentiale

Vestibulum processus calor repugnant ferro castings

Ad productionem summus qualitas calor repugnant ferro artus castings Exigit specialized foramina ars ut bene proprietatibus in ultima uber.

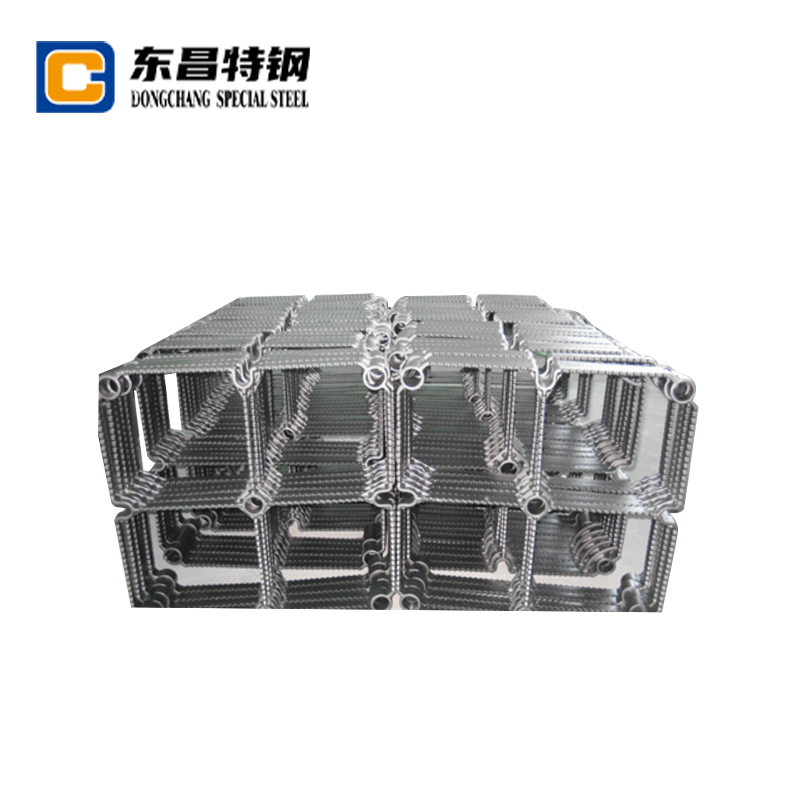

Iactu modi

Plures mittentes modi adhibentur fretus pars magnitudine et multiplicitate:

- Arena proiciens pro magna, complexu figuris

- Investment mittentem pro praecisione components

- Centrifugal proiectio cylindrical partes

Calor curatio considerations

Post-casting calor treatments sunt discrimine ad consequi desideravit microstructure et proprietatibus. Haec includit:

- Solutio annealing ad dissolvere carbides

- Stabilization treatments ne sensitization

- Accentus reliing ut minimize residualem passiones

Sustentationem et Lifespan Tractus Strategies

Propriis sustentationem potest significantly extend in ministerium vitae Longum diuturna æstus resistant ferro Frames , Reducing postea costs et downtime.

Inspectionem artes

Auxilium Aquilonem ordinare potentiale proventus ante se ducunt ad defectum:

- Visual examination for rimas et distortione

- Ultrasonic temptationis ad internum defectibus

- Dimensional checks quia reprehensio deformatio

Restituo modi

Cum damnum occurs, plura reparare options est:

- Welding cum matching filler metalla

- Metal Sutiting pro Crack Restituo

- Protective coatings ut restituo superficiem integritas

Future trends in calor resistant ferro castings

In progressionem novi alloys et vestibulum artes continues ad ventilabis ad terminos quid suus 'maxime cum calor repugnant ferro artus castings.

Provectus Alloy Development

Inquisitores sunt operantes in nova compositiones cum:

- Altior temperatus capabilities

- Improved oxidatio resistentia

- Melius scelerisque lassitudine resistentia

Eminentive vestibulum

3D printing technologiae sunt adapted calor repugnant ferro components, offering:

- Complexu geometries non potest cum traditional casting

- Reducitur materia vastum

- Caster Prototyping Capabilities

+86-15861061878

+86-15861061878